Prototyping Department

Prototyping Capabilities

With over 20 unique projects annually, our prototyping capabilities cover small series and custom-builds:

- From 75 to 200 units per year

- Specialized in direct liquid cooling and immersion cooling systems for both single and dual-phase applications

- Custom cooler development and iterative prototyping to meet your exact thermal and mechanical constraints

Our manufacturing capabilities in Strasbourg

Inspection & Testing Tools

- Optical Inspection Microscope: essential for precise inspection and manipulation of miniature components.

- High-magnification optics

- Anti-glare lighting

PCB Assembly & Soldering

- Yihua 853D – Soldering & Rework Station: versatile soldering station for assembling and repairing PCBs.

- Integrated soldering iron and hot air gun

- Optimized for SMD component rework

- Tecprint 700 – Manual Stencil Printer: manual screen printer for applying solder paste to circuit boards.

- Max stencil size: 310 × 470 mm

- Min stencil size: 50 × 50 mm

- Max PCB size: 300 × 400 mm

- FT05 Reflow Oven: compact thermal reflow oven for surface mount soldering.

- Usable board area: 350 × 400 mm

- Max temperature: 300°C

- High-Precision SMD Manipulator & Syringe Stand: manual placement station for SMD components.

- Work area: 300 × 500 mm

- Ideal for prototyping and fine-pitch placement

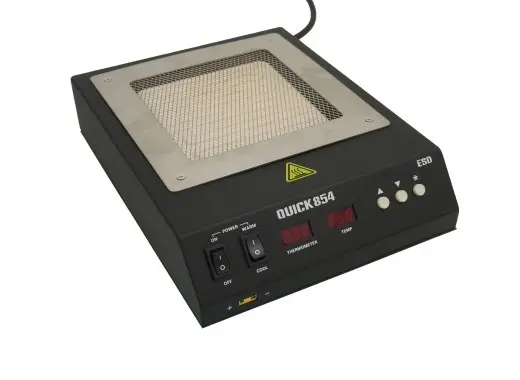

- Infrared Preheating System: reduces thermal stress during soldering operations.

- Power: 400W

- Heating surface: 130 × 130 mm

Yihua 853D

Tecprint 700

FT05 Reflow Oven

High-Precision SMD Manipulator

Infrared Preheating System

Metal Forming & Fabrication

- Amada ITPS 5012 – CNC Press Brake: high-precision hydraulic press brake for sheet metal forming.

- Bed length: 1200 mm

- Tonnage: 50 tons

- MIG/MAG Welding Station – 160A: versatile arc welding system for metal assembly and repair.

Milling & Machining

- FCA 500 CNC – 3-Axis Machining Center: CNC milling machine for precision part fabrication.

- Table length: 1220 mm

- Suitable for aluminum, steel, and composite machining

Amada ITPS 5012

MIG/MAG Welding Station

FCA 500 CNC

Cutting & Engraving

- CO₂ Laser Cutter: high-power laser cutting system for prototyping and production.

- Laser power: 300W

- Work area: 130 × 90 cm

- Cutting thickness: 0–20 mm (varies by material)

Cable Preparation & Wiring

- Automatic Wire Crimping Machine: designed for high-speed cable harness assembly.

- 2 workstations

- Up to 4,000 wires per hour

- Compatible with 26–10 AWG wire sizes

- Autosplice 2000 – Y-Connection Splicing Machine: automated splicing equipment for Y-type wire connections.

- Fast and secure multi-branch wire connections

CO₂ Laser Cutter

Automatic Wire Crimping Machine

Autosplice 2000

Our manufacturing capabilities in Manchester

CNC Machining Capabilities

We operate six CNC vertical machining centers, specialized for high-precision aluminum machining:

-

3× XYZ VMC 560

Travel: 560mm (X) × 400mm (Y) × 500mm (Z)

Table size: 510mm -

2× XYZ 710

Travel: 710mm (X) × 450mm (Y) × 510mm (Z)

Table size: 710mm

(One currently stored and unserviceable) -

1× XYZ 750

Travel: 750mm (X) × 440mm (Y) × 500mm (Z)

Table size: 750mm

Machining performance:

- Material: Aluminum (up to 90mm thick)

- Tolerance: ±0.01mm

- Equipped with:

- Tool Measuring Probes accurate to ±0.003mm

- 3D Probing Systems accurate to ±0.003mm

- LOSMA Galileo Plus LEV Extraction Modules on all machines for clean operation

Cutting & Engraving

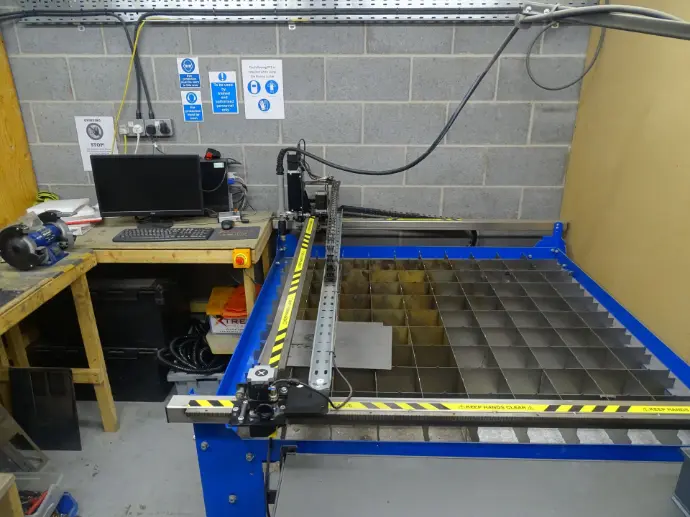

- R-Tech CNC Plasma Cutter

- Bed size: 2.1m × 2.1m

- Cuts steel up to 12mm thick

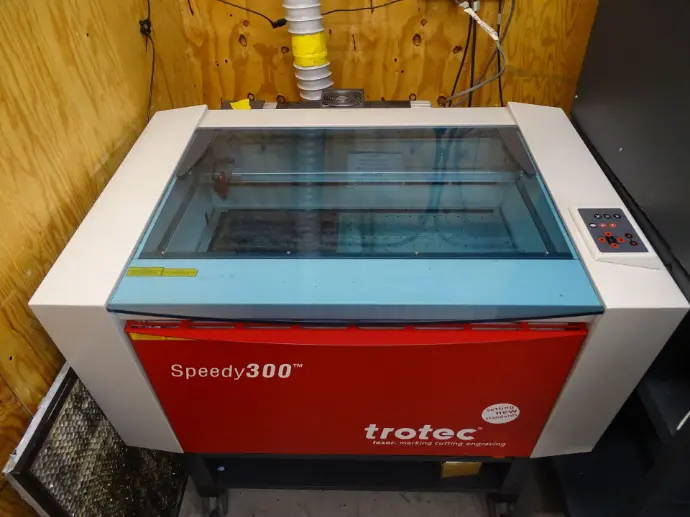

- Trotec CNC CO₂ Laser Cutter/Engraver

- Bed size: 700mm × 400mm

- Cuts and engraves plastic up to 10mm thick

- Gravograph Jag Laser Engraver

- Engraving area: 250mm × 250mm

- Ideal for metal tags, plaques, and small-format component ID

Surface Finishing & Coating

- Custom Anodising Line: designed in-house for protective and decorative finishes

- Powder Coating Booth & Oven: Booth: 1.4m × 1m / Oven: 1.6m × 1m

- Bead Blasting Cabinet (MATTIS): uniform matte finishes and prep work

- Paint Spray Machine (T-Mech)

- Custom Metal Brushing/Polishing Station: for mirror or directional finishes

- Pedestal Twin Head Buffing Machine: 1m high, 0.8m wide

Inspection & Testing Tools

- 3× Colour Meters: FRU & AMT models

- 3× Thickness Testers: Eoteck NTK 127s

- Thermal Imaging Camera: FLIR TG165

- Thermal Test Oven: for component reliability testing

- Decibel Meter: TENMA 72-860 for acoustic analysis

Fabrication & Manual Tools

- Pillar Drill (Performance Power Tools PP2505BD)

- Grinder (Einhell BT-BG 150)

- Belt Sander (Scheppach)

- 10-Tonne Pneumatic Fly Press

- Draper Extraction System with pipe ducting & LEV hood

Production & Assembly

- 2 Custom ESD-Protected Production Lines

- Integrated end-test rigs for product validation

- 1 Custom Packing Line

- Optimized for safe handling and shipping

Power & Support Systems

- Kaeser HPC SX6 Screw Compressor

- 500A & 1000A Rectifiers by Jacquet Weston Engineering

- 2× Tae Evo Chillers (ICI 121): stable cooling for sensitive equipment

- 1× Crown 30WRTT Pallet Reach Truck: for material flow and heavy lifting