2CRSi Manufacturing Facilities

First factory — Strasbourg, France

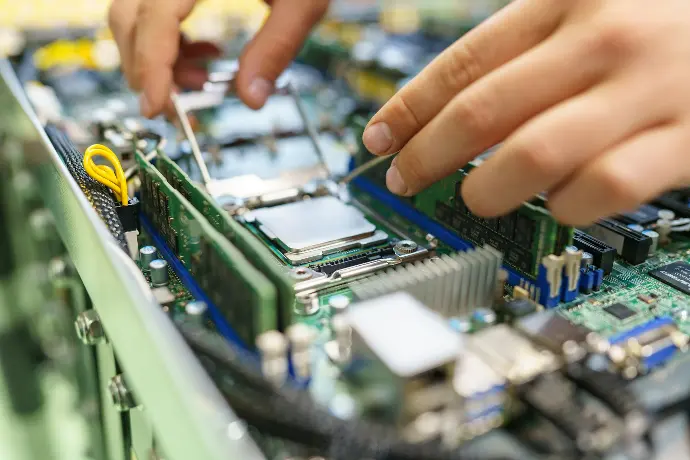

At the heart of our industrial capabilities, our Strasbourg facility stands as a cornerstone of innovation and high-performance manufacturing since 2005. Designed to meet the demands of today's most advanced computing infrastructure, this facility delivers a seamless and secure server integration experience at scale.

Annual Capacity

Our Strasbourg facility is built for scale. With an annual integration capacity of up to 50,000 server units, it supports large deployment cycles while ensuring precision and consistency.

On-Site Integration & Manufacturing Capabilities

Our Strasbourg site is equipped with cutting-edge technology and certified processes to ensure the highest standards of quality, security, and compliance:

- Confidential Integration & Testing Facility – dedicated testing and production lines including trained, certified staff to support sensitive projects.

- Mechanical Prototyping Lab – for custom hardware design, rapid prototyping, and bespoke system integration.

- In-House Certification Management – ensuring all systems comply with:

- Comprehensive RoHS Compliance Management

Ensuring full conformity with the Restriction of Hazardous Substances directive to promote environmentally responsible manufacturing. -

Oversight of REACH Certification Processes

Managing the Registration, Evaluation, Authorization, and Restriction of Chemicals to guarantee material safety and regulatory alignment. -

Commitment to APAVE Certification Standards

Upholding rigorous operational safety and performance excellence through recognized APAVE protocols. -

CE Compliance

Meeting essential European health, safety, and environmental protection requirements with CE-marked processes and products.

- Comprehensive RoHS Compliance Management

CE

ROHS

REACH

APAVE

Advanced Testing Infrastructure

Our Strasbourg facility offers advanced testing capabilities to ensure peak performance and reliability across all server types and cooling technologies:

- Air-Cooled Testing Benches (19” and OCP)

- Direct-on-Chip Liquid Cooling Benches

-

Immersion Cooling Test Benches (19” and OCP) with compatibility for immersion tanks from leading manufacturing companies:

- Submer

- Asperitas

- GRC

Second factory — Manchester, UK

Located in the heart of the United Kingdom, our Manchester facility is a state-of-the-art site dedicated to high-performance Edge solutions integration and advanced manufacturing. With an annual production capacity of up to 10,000 edge systems units, this site plays a pivotal role in our global operations.

Core On-Site Capabilities

Precision CNC Machining

We specialize in high-accuracy CNC manufacturing, delivering custom components and enclosures tailored to your specific design requirements. Our state-of-the-art equipment ensures consistent quality, tight tolerances, and fast turnaround times.

Custom Tools & Molds, Made In-House

Our in-house machining capabilities empower us to design and manufacture custom tools and molds tailored precisely to your application needs we deliver mechanical solutions that optimize fit, performance, and reliability.

Our facility ensures:

- High Precision: tight tolerances, tailored finishes, and robust materials

- Design Flexibility: custom molds and brackets for non-standard enclosures, thermal modules, or unique I/O layouts

Compliance & Certification Management

We maintain rigorous standards for quality, safety, and environmental responsibility through comprehensive compliance protocols:

-

RoHS Compliance

Full adherence to the Restriction of Hazardous Substances directive to ensure safe and sustainable manufacturing practices. -

REACH Process Management

Proactive management of Registration, Evaluation, Authorization, and Restriction of Chemicals for chemical safety and traceability. -

Certified Standards

- APAVE-certified for safety and reliability

- ISO 9001: Quality Management System

- ISO 14001: Environmental Management System

- NATO compliance for defense-grade requirements

ROHS

REACH

APAVE

ISO 9001

ISO 14001

NATO

Third factory — Plattsburgh, NY, USA

Since 2021, our Plattsburgh facility, strategically located in New York State, is equipped to handle up to 10,000 server integrations per year. This advanced site combines rigorous compliance standards with cutting-edge testing capabilities to support a wide range of computing solutions.

Advanced Testing Facilities:

- Air-Cooled Bench Testing for 19” and OCP-compliant systems

- Immersion Cooling Test Benches for 19” and OCP form factors, supporting single-phase and dual-phase immersion cooling technologies

Key Manufacturing & Integration Capabilities:

- Full RoHS (Restriction of Hazardous Substances) compliance management

- REACH (Registration, Evaluation, Authorization, and Restriction of Chemicals) certification process oversight

- Adherence to APAVE certification standards for operational safety and excellence

ROHS

REACH

APAVE

Fourth factory — Upcoming: Chennai, India

Our upcoming CH4 facility in Chennai, India, is set to expand our global manufacturing footprint with a planned capacity of 10,000 server integrations per year. Strategically positioned to serve the growing demand in the Asia-Pacific region, this factory is designed to deliver both efficiency and compliance from day one.

Planned Manufacturing & Integration Capabilities:

- Full BIS (Bureau of Indian Standards) certification process management to meet local regulatory requirements

Upcoming Testing Facilities:

- Air-Cooled Testing Benches for 19” and OCP-compliant infrastructure

- Immersion Cooling Test Benches for 19” and OCP systems, supporting advanced cooling technologies